Could Your Town Host a Gigafab?

by Mark Hagedorn

This article was originally published in pv magazine - November 2022 edition.

With landmark legislation set to devote billions of dollars to develop a clean energy supply chain for the United States, developers will be busy poring over maps to decide where the first green jobs will land. CEA’s Mark Hagedorn looks at the qualities that make for the perfect gigafactory site.

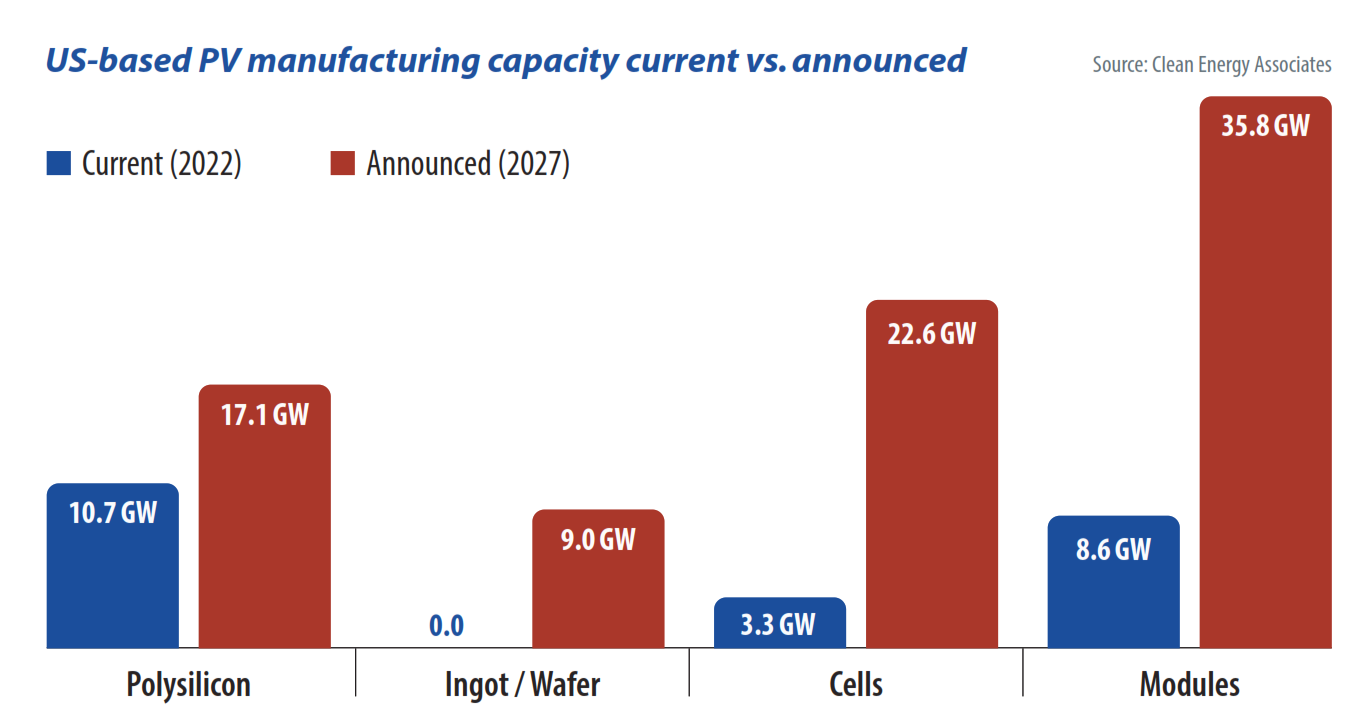

President Joe Biden’s ambitious Inflation Reduction Act (IRA) is injecting the US economy with $369 billion of new federal incentives for clean energy projects. To unlock the full potential of the bill, and its domestic manufacturing incentives, a new clean energy supply chain must be developed in the US. As a result, domestic clean energy manufacturers have already begun announcing significant increases in US production capacity (see chart below). The challenge of site selection for this increased number of production lines will now be center stage.

The electric vehicle (EV) sector saw tax credits renewed under the legislation but most of the EVs on the market today would not qualify for domestic production incentives without a waiver. Likewise, today’s Asian-led supply chain for solar panels, inverters, and batteries would miss out on the 10% adder available on top of the usual 30% investment tax credit (or the corresponding production tax credit) unless at least 40% of the content is sourced in the United States - and the level of that domestic content requirement is set to rise over time. Demand for US-made clean energy products is stronger than ever and the IRA represents a long-term shift in strategy to increase domestic supply.’

International and domestic companies alike are scrambling to sign offtake agreements and construct new solar and storage gigafactories to build out the US supply chain. However, the mobilization will take time and will rely on navigating varying local and state-specific rules and development processes. Without local knowledge of the key players and nuances associated with planned factory sites, missteps can be expensive to remedy. But what are the primary challenges you need to address to ensure you get it right the first time?

Key Incentives

Along with the new federal incentives, many local and state governments have stimulus packages to entice manufacturers. But if you’re basing your selection on a desktop review from thousands of miles away, you may not have the rapport and local insight that opens the doors to meetings with the county official or local economic development office which is likely to have a greater understanding of the city and county’s incentives.

Identifying local organizations and officials with which to build working relationships is critical to understanding what’s possible. Doing so maximizes the economics of a prospective gigafactory.

Workforce Issues

Finding areas with the most beneficial incentives is one hurdle to overcome; ensuring an available workforce is another. For example, many coal producing regions have been targeted with incentives in the IRA to help displaced coal workers join the green transition. However, with the recent rapid decommissioning of coal plants, many young workers have already moved on to find work elsewhere.

A gigafactory may have the potential to create up to 5,000 well paid jobs but developing a reliable, well-trained workforce in a rural area takes time. Nurturing a green workforce is a priority of the IRA, with the fullest benefits of its clean energy tax incentives tied to apprenticeship programs and prevailing wage requirements. It is critically important to ensure the location for your gigafactory can supply and train enough workers.

Logistical Considerations

A comprehensive logistics study can identify factors that make or break the margins of a prospective gigafactory. In the short-term, before the US clean energy supply chain matures, gigafactories are likely to remain dependent on foreign suppliers for most of their battery and solar components and materials.

For example, co-locating near the deep-water ports along the Gulf Coast, with their connective web of shipping, truck, and rail routes spreading into the country, could be a logistical dream. That would reduce transportation costs significantly versus a landlocked site in the mountainous west, for both component imports in the short term and the potential for energy technology exports abroad in the long run. Such sites will sell for a premium, though, requiring a cost-benefit-analysis.

Utility Concerns

Brand new gigafactories will necessitate new infrastructure such as transmission lines, water, waste management, and gas infrastructure.

Early coordination with utilities is important to avoid costly delays and unwelcome surprises. For example, just look at the backlog of utility upgrades already gumming up wind and solar expansion in the United States.

Depending on your location, you may face unexpected costs due to local transmission constraints as you deal with utility partners ranging from a rural electric co-operative utility, with limited staff; to a large company with multiple utility feeds serving your site. Regardless, sound energy models, to forecast the needs of your sites and account for the various voltages required and service needs over multiple years, will ensure the best procurement strategy.

Geographic Factors

The physical condition of a potential site, and the weather patterns that could affect it, are additional key factors that can’t always be determined via a website or generally available information. If significant grading is needed to level the site, or half the footprint is required for stormwater runoff infrastructure, that adds cost and could reduce the square footage potential of your building.

Potential exposure to natural disasters is also an important factor to consider. For example, the Gulf Coast has favorable logistics, incentives, and a willing workforce but hurricanes and storm surges could stop production for weeks at a time.

Repurposing brownfield sites is a popular idea, but unforeseen environmental remediation costs can quickly tank the economics of a new factory. It is also worth considering whether areas that receive a lot of snow will find worker absenteeism a problem during the winter months.

Navigating site selection is the critical first step for the development of a successful gigafactory in the US. It requires boots on the ground to prevent delays and expensive mistakes.

There are perfect sites that check off all these boxes, but you may find yourself competing with bids lodged for a big box distribution facility or a new data center. Unless you’re able to compete with the biggest players for the most desirable sites, local knowledge encompassing all the important factors cited above can help determine which project sites are viable.